What are Outdoor LED Linear Lights? A Comprehensive Guide

With the rapid development of smart cities and green buildings, it has become the core lighting solution to improve the quality of night scenes, enhance safety, and achieve energy conservation and emission reduction. This article will deeply interpret the outdoor linear lights from the "five key points": definition, components, application scenarios, selection guide, and installation advantages and precautions, to help you quickly grasp the key information of the whole process of project implementation.

1. What is an outdoor linear light?

Outdoor LED linear lights are lighting devices that arrange multiple LED lamp beads along a straight or curved channel, designed to provide a seamless and continuous light strip effect for long distances or large areas. Unlike indoor linear lights, outdoor models are designed to be windproof and dustproof, and usually use a rugged housing and sealed structure with an IP65 or higher protection level to ensure stable operation in harsh environments. The IP65 rating prevents low-pressure water flow and all dust from entering from any direction, while IP68 can withstand short-term immersion and ensure that it is not affected by heavy rain and high-pressure cleaning. The service life of the high-efficiency LED chips is more than 25,000 hours, and light efficiency reaches 100-150 lm/W because they are welded on aluminum-based circuit boards and equipped with specialized heat sinks. In addition, outdoor linear lights must withstand a temperature range of -40 ℃ to +55 ℃ to ensure reliable lighting in different climatic conditions throughout the year. In comparison, indoor linear lights are mainly protected with IP20 or IP30 ratings, which means they can only operate in controlled, dry environments. They cannot withstand outdoor moisture and dust, and therefore do not have the durability and safety of outdoor use.

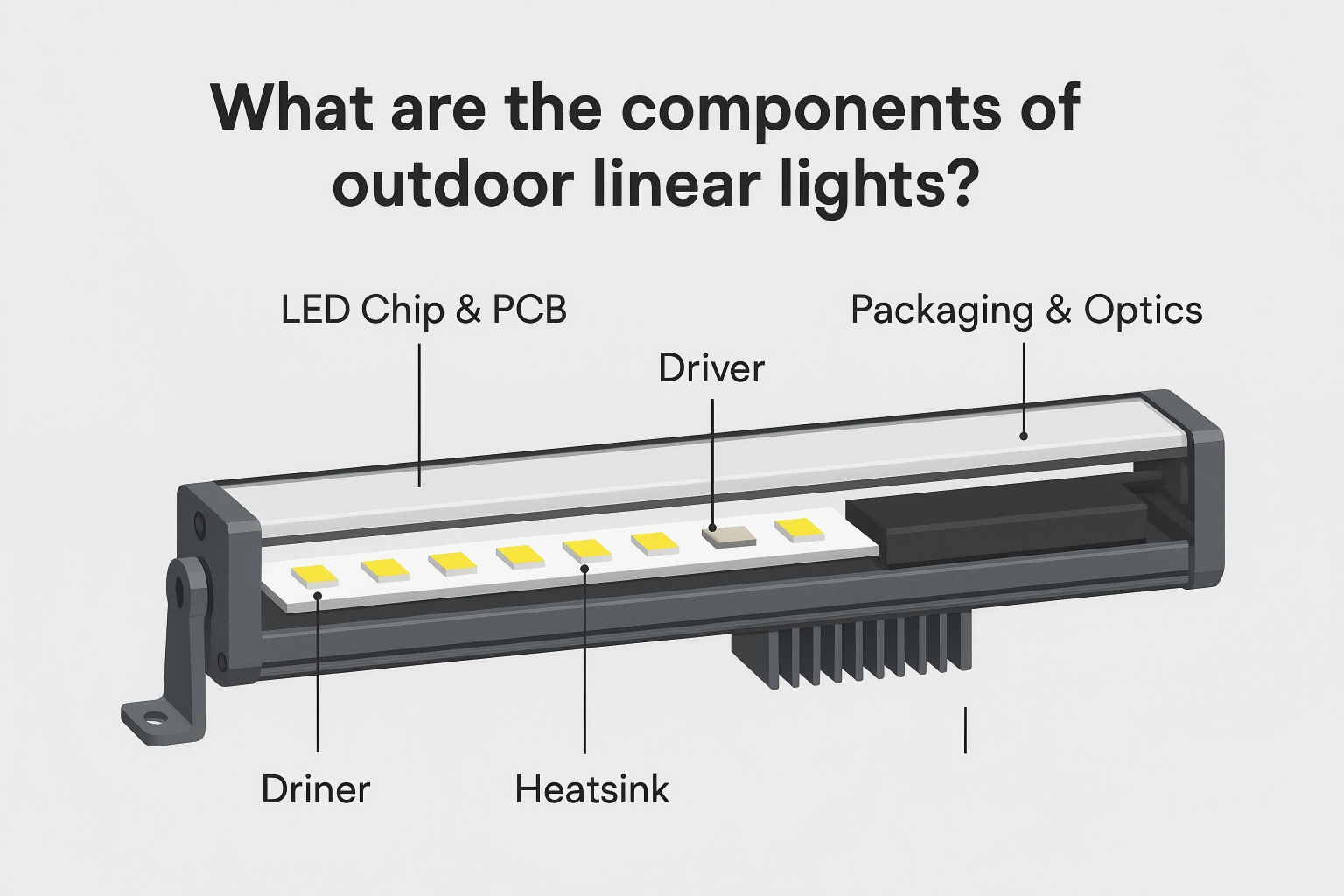

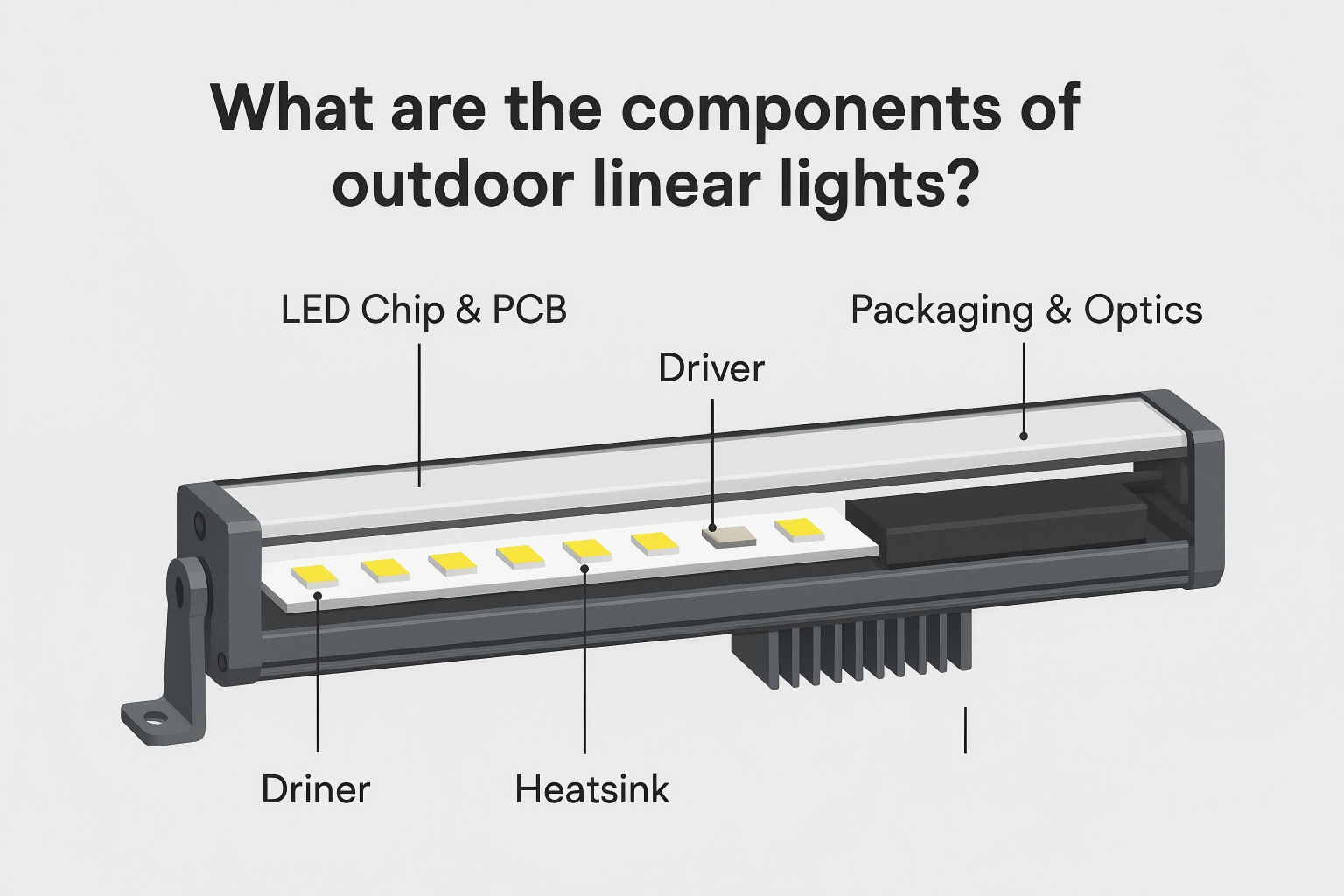

2. What are the components of outdoor linear lights?

2.1)LED chip & PCB: Determines light efficiency and lifespan

The LED chip is the core light-emitting unit of the whole lamp. Common packaging forms include COB (Chip on Board) and SMD (Surface-Mount Device); different packages have a significant impact on light efficiency and heat dissipation performance.

Metal substrate (MCPCB) is commonly used in the PCB of LED linear lights. It effectively conducts heat by soldering the LED chip on an aluminum or copper substrate to ensure that the chip can still maintain optimal luminous flux and long life under high driving conditions.

2.2)Driver: Constant current vs constant voltage driver and its selection points

The driver is used to stabilize the input power supply and provide accurate current or voltage to the LED chip. Common models are divided into constant current drivers (350–1,500 mA) and constant voltage drivers (12 V/24 V).

When selecting the model, the voltage drop needs to be calculated based on the length of the lamp body, power requirements, and wiring distance to avoid flickering and life attenuation caused by insufficient terminal brightness or driver overload.

2.3)Heatsink: Relationship between aluminum profile structure and heat dissipation performance

The heat sink generally uses high thermal conductivity aluminum profiles, and increases the contact surface with the air through large-area heat dissipation fins, effectively dissipating the heat generated by the LED during operation and maintaining the chip within a safe operating temperature range.

Reasonable fin spacing design and surface treatment (such as anodizing) can further improve the efficiency of thermal radiation and convection, thereby extending the overall life of the lamp.

2.4)Packaging & Optics: Diffuser Cover Material (PC/PMMA) and Its Effect on Light Distribution

Diffuser covers are usually made of polycarbonate (PC) or polymethyl methacrylate (PMMA) materials, which have excellent light transmittance and UV resistance, and can ensure long-term stable optical performance in outdoor environments.

Different cover materials and texture designs will affect the light dispersion and distribution angle. Common diffuse and focusing diffusers can meet the needs of uniform wall washing or directional focusing, respectively.

2.5)Shell & Seals: Corrosion-resistant aluminum alloy and waterproof seal ring grade

The lamp body shell is mostly made of marine-grade aluminum alloy, which has excellent corrosion resistance, UV resistance and impact resistance, and can be used for a long time in harsh outdoor environments.

With silicone seals and high-quality waterproof glue, the overall protection level can usually reach IP65, IP66, or even IP68, ensuring the sealing reliability under dust, water jets, and even short-term immersion conditions.

3. Application scenarios of outdoor linear lights

Outdoor LED linear lights are ideal for multi-scene lighting due to their waterproofness, high brightness, and design flexibility. The following are its core application areas and advantages:

3.1)Commercial buildings and urban landscapes

Architectural outline lighting: outline the lines of high-rise buildings, bridges, or monuments to enhance nighttime recognition (such as using IP67 waterproof linear lights with 3000K warm light).

Dynamic advertising and logos: Use RGB color-changing lamps to create eye-catching effects for brand signs and shopping mall windows, and support holiday theme switching (such as SloanLED ColorFlow series).

Squares and pedestrian streets: Embedded in the ground or hung on the eaves, they provide uniform lighting and reduce the risk of pedestrians tripping.

3.2)Residential and courtyard landscaping

Gardens and pools: IP68-rated underwater linear lights can surround pools or flower beds to create a resort-style atmosphere (low-voltage 12V design ensures safety).

Porches and driveways: Install anti-glare lamps (beam angle ≤ 30°) to illuminate the path without disturbing neighbors.

Fences and terraces: Hidden installation highlights the building structure, and smart sensors are used to achieve "lights when people come".

3.3)Public facilities and industrial areas

Parking lots and warehouses: High-lumen (10,000+ lm) linear lights are paired with impact-resistant housings to meet 24/7 lighting needs and reduce monitoring blind spots.

Transportation hubs: Subway platforms and airport corridors use weather-resistant lamps (-40°C to 50°C tolerance) to ensure visibility in extreme weather.

Roads and tunnels: Linear lights replace traditional sodium lamps to reduce flicker and improve uniformity (in compliance with EN 12464 road lighting standards).

3.4)Festivals and temporary installations

Event venues: When setting up temporary exhibitions, bendable LED light strips (such as silicone materials) can easily shape arches and stage outlines.

Art installations: Combined with control systems, the lights can change dynamically with music or crowds to enhance the interactive experience.

By adapting to scene requirements, outdoor LED linear lights can not only improve the functionality and aesthetics of the space, but also reduce energy consumption by more than 50%. They are the main lighting force for smart cities and green buildings.

4. How to choose suitable outdoor linear lights

When choosing outdoor LED linear lights, the following four parameters should be compared in combination with the functional requirements and aesthetic requirements of the project: brightness, light distribution, color temperature and installation method to ensure that the final lighting effect not only meets visibility and safety, but also integrates into the overall design style.

4.1)Brightness

Brightness is measured in lumens (lm), which directly determines the brightness and visible distance of the lighting; high brightness can enhance safety and visibility, while low brightness is more atmospheric and energy-saving.

The choice should be made according to the application scenario: path lighting can choose 300-800 lm/m to ensure visibility on the ground; facade wall washing or large-area lighting requires 800-2 000 lm/m to highlight details and contours; parking lots and other safe places recommend 10 000+ lm/fixture to eliminate shadow areas and improve monitoring effects.

4.2)Beam Angle

The beam angle (°) reflects the range of light diffusion, affecting the irradiation width and light intensity distribution; narrow beams (15°-30°) focus and are suitable for facade wall washing and accent lighting, medium beams (30°-60°) take into account both range and intensity for small paths and billboards, and wide beams (60°-120°) are used for large-area uniform lighting such as squares and parking lots.

4.3)Color Temperature

Color temperature is measured in Kelvin (K) to indicate the warmth or coldness of light, which directly affects the atmosphere and visual comfort of the space. Warm white light (2,700–3,000 K) creates a warm atmosphere and is suitable for commercial and landscape decoration. Neutral white (3,500–4,000 K) balances function and comfort and is mostly used in public spaces. Daylight white (5,000–6,500 K) improves detail clarity and is commonly used in security lighting and industrial areas.

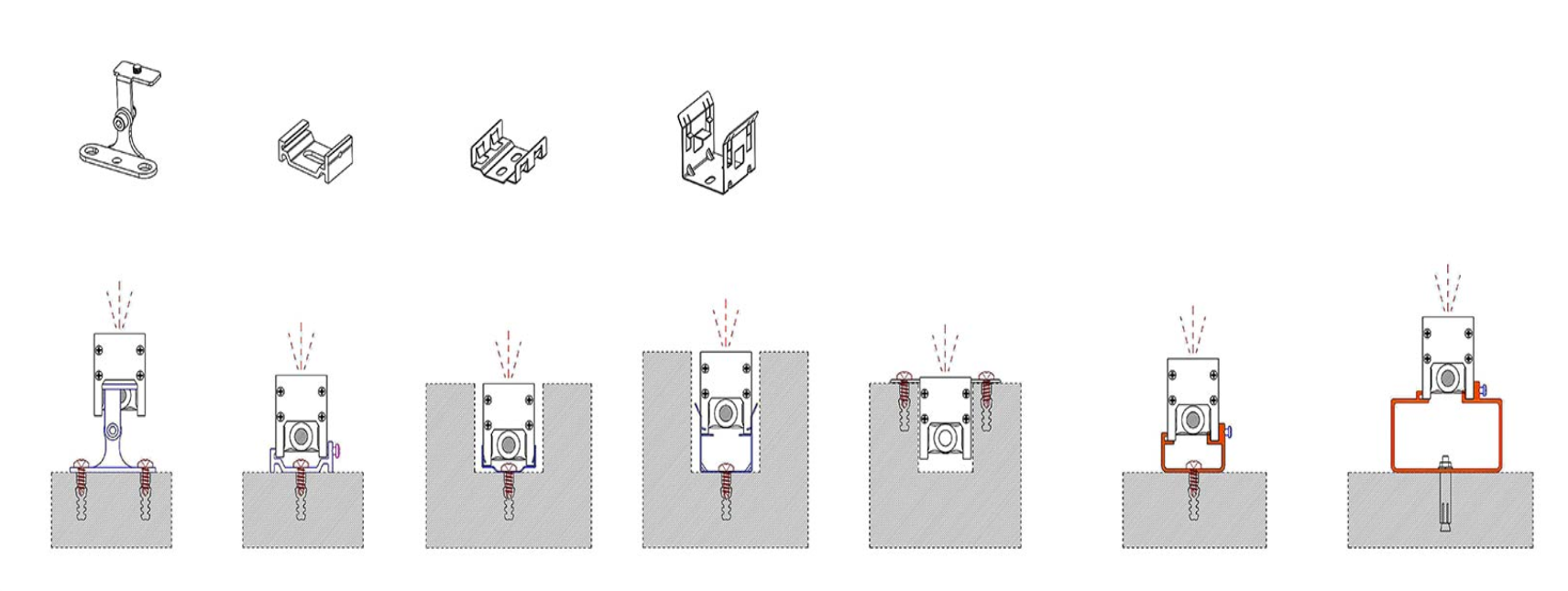

4.4)Mounting Style

Surface installation:

No need to dig, directly fix it to the wall or eaves, easy to construct, suitable for most scenes.

Embedded: The lamp body is hidden in the ground or ceiling, which is more visually concise and requires reserved installation space. It is commonly used in path and underground lighting.

Suspended: The lamp is suspended in the air, suitable for elevated spaces or under bridges. The height and direction can be flexibly adjusted with chains or steel cables.

5. Main advantages of installing outdoor linear lights

Outdoor LED linear lights not only revolutionize lighting technology but also bring multiple values to various projects through energy efficiency, durability, and design innovation. The following is an in-depth analysis of its core advantages:

5.1)Energy efficiency and cost advantages

Ultra-high energy efficiency ratio: The luminous efficiency of LED linear lights reaches 120–200 lm/W, which is more than 50% energy-saving than traditional high-pressure sodium lamps (about 80 lm/W), significantly reducing electricity bills. For example, replacing 1,000 meters of road sodium lamps with LED linear lights can save more than 100,000 yuan in electricity bills per year (calculated at US$0.15/kWh).

Long life reduces maintenance costs: 50,000–100,000 hours of life (about 10–20 years), reducing the manpower and material costs of frequent bulb replacement. Compared with metal halide lamps (life of about 5,000 hours), the comprehensive maintenance cost is reduced by 70%.

5.2)Ease of maintenance

Modular design: In case of failure, only a single-segment module needs to be replaced, without the need for overall removal, saving maintenance time (such as Hubbell LPL series supports hot-swap replacement).

Self-cleaning surface: Dust-proof and anti-fouling coatings (such as nano-titanium dioxide) reduce dust accumulation, and only need to be wiped with clean water once a year to maintain light transmittance.

5.3)Environmental adaptability

Extreme climate tolerance: High-quality models support -40°C to +60°C operation (such as Philips Xitanium drive), suitable for the Arctic Circle or desert areas.

Waterproof and anti-corrosion: IP68+316 stainless steel housing resists salt spray and acid rain, suitable for coastal chemical plants or ship docks (case: Dubai Palm Island underwater lighting project).

5.4)Design flexibility

Various forms: bendable (R ≥ 10cm), spliced or cut (such as Osram FlexLED), suitable for curved buildings or special-shaped landscapes.

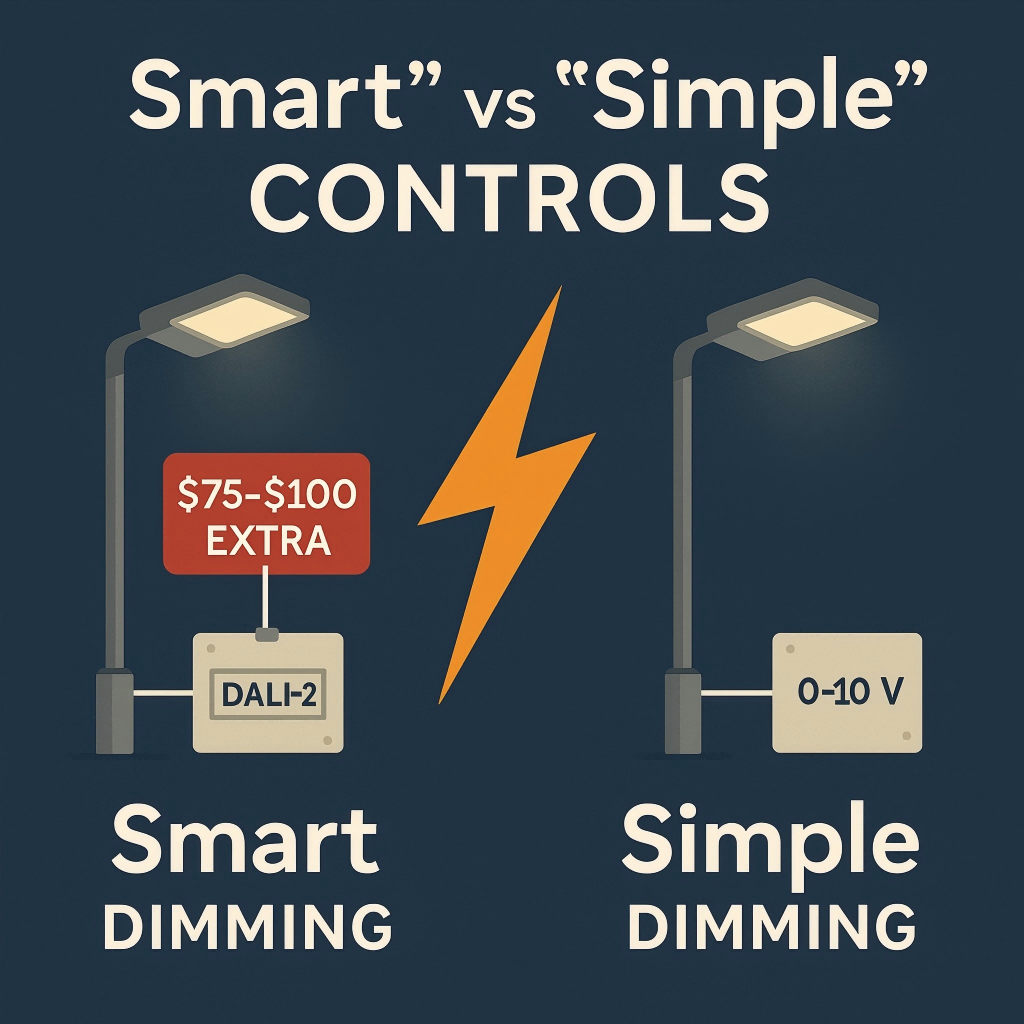

Intelligent control: compatible with DALI/Zigbee system, realize zone dimming, timer switch, or linkage security camera (such as Signify Interact Landmark system).

5.5)Value-added effect

Aesthetics and brand enhancement: dynamic RGBW lighting can customize corporate LOGO color (such as Apple headquarters night lighting logo), enhance brand recognition.

Real estate value gain: research shows that high-quality outdoor lighting can increase residential sales price by 5–7% (data source: National Association of Realtors).

Safety and compliance: meet international standards (such as EN 12464 road illumination requirements), reduce the accident rate in public areas, and avoid legal disputes.

6. Precautions for installing outdoor linear lights

During the construction and acceptance stage, pay attention to the following five key points to ensure the stable, safe, and long-life operation of outdoor linear lights.

6.1)Power supply matching: constant current vs constant voltage, power supply distance

Constant current drive (Constant Current): Provides stable current (350-1,500 mA), suitable for high-power, long-distance series line lights to prevent brightness attenuation at the end;

Constant voltage drive (Constant Voltage): Outputs fixed voltage (12 V/24 V), commonly used in flexible light strip systems with short-distance or segmented power supply.

Voltage drop calculation: The longer the wire, the greater the current, and the more obvious the voltage drop. The voltage drop needs to be calculated according to the wire diameter and distance (generally not more than 3-5% of the input voltage) to avoid dimming of the end lamps or overloading of the driver.

6.2)Wiring and grounding: waterproof connector, GFCI protection, reasonable grounding scheme

Waterproof connector: Use silicone-filled wire caps or special dry connectors (DryConn, etc.) to block water vapor intrusion and prevent contact oxidation.

GFCI protection: According to NEC requirements, all outdoor 125 V single-phase sockets must be equipped with leakage protectors; low-voltage systems can choose distribution boxes or modules with GFCI.

Grounding scheme: All metal shells must be reliably grounded, use green/yellow two-color grounding wires and maintain low impedance, and install lightning arresters or surge protection devices when necessary.

6.3)Thermal management: maximum power density, heat sink installation spacing, ambient temperature limit

Ambient temperature: In extremely cold (< –40 °C) or hot (> +55 °C) environments, wide temperature drivers and enhanced heat dissipation designs must be used. Tests must be performed to confirm that the luminous flux and electrical performance of the components meet the specifications under extreme temperatures.

6.4)Waterproof test: IP test method, on-site splash/jet test standard

IP65 spray test: 6.3 mm nozzle, 3 m distance, 12.5 L/min water flow, test 1 min/m² (minimum 3 min).

IP68 immersion test: immerse in water ≥ 1 m for 30 min (or longer as specified by the manufacturer) to confirm that there is no water seepage.

Additional suggestions: For bridges or high-pressure cleaning scenarios, consider IP69K (high-pressure and high-temperature spray) testing to prevent damage from strong water column impact.

6.5)Maintenance planning: periodic inspection, cleaning guide, driver replacement process

Cleaning method: Use a clean soft cloth or low-pressure water gun to remove dust, fallen leaves and stains; avoid using corrosive detergents to avoid damaging the diffuser and sealant.

Driver replacement: If flickering, abnormal output voltage/current, or overheating is detected, disconnect the quick connector after power off, match the new driver according to the original specifications (current, voltage, power), and keep maintenance records.

By strictly implementing the above precautions, not only can the stability and safety of outdoor linear lights be guaranteed, but also the service life can be extended, the operation and maintenance costs can be reduced, and the long-term and efficient operation of the project can be ensured. If you need in-depth technical support or on-site commissioning services, please contact the professional engineering team.

Conclusion

Through a comprehensive description of the definition, composition, application scenarios, selection points, installation advantages and precautions of outdoor LED linear lights, we can see that this lighting solution has significant advantages in improving urban night views, security, energy conservation and emission reduction, and landscaping. Overall, outdoor LED linear lights have become the core tool for nighttime lighting in smart cities and green buildings, bringing long-term economic and environmental benefits to projects. I hope this article can help you quickly grasp the key points in project planning and implementation, and achieve efficient, reliable, and creative outdoor linear lighting effects.

Illuminate Your Building's Future Now with LNJAMI.

We are a 17-year-old outdoor lighting source factory. Our main products are outdoor wall washers, linear lights, floodlights, point light sources, and other lamps. We generally adhere to providing customers with safe, reliable, and cost-effective products, and we have always paid attention to the protection of LED lamps. We can provide DC12V, DC24V, and AC220V lamps according to customer needs, and we can also provide customized lamps. If you have lighting project needs, please contact us.