IEC Protection Classes For LED Luminaires (2025)

In the modern era of lighting, technologies change at a rapid rate accompanied by increasing concerns regarding safety and efficiency. As LED luminaires dominate both residential and commercial projects, these types of lights must be properly classified by their protection classes for respective compliance and safety purposes. This article provides a thorough, up-to-date guide encompassing all available information and regulations covering IEC protection classes as of 2025.

1. Extended Overview of IEC Protection Classes

These classes are fundamental for the design and use of LED Luminaires. They ensure that every device designed and installed is safe to use and functions properly. In 2025, these classes have changed to include new improvements like modern technologies and better insulation, which provide more protection to the user in residential and commercial settings.

What Are IEC Protection Classes?

The IEC Protection Classes outline the level of protection a luminaire provides in terms of an electrical shock. These classes are provided by the International Electrotechnical Commission (IEC) and, like everything else, are continuously reviewed regarding safety and technological changes. The standards available today classify LED luminaires into four distinct classes:

Class 0: This is a classification of the least insulation, relying solely on the insulating material (such as PVC), with no protective earth (PE) connection. It is almost completely obsolete in modern technology because of the extreme safety concerns associated with it, but it has some historical evidence such as the old vintage two-pin plug gadgets and fairy lights for Christmas.

Class I: These include other types of Safety Measures built into the device. At least Built-in safety devices basic insulation is provided together with an earth (or ground) connection. There are other advanced methods built in such as the earth wire that enable any fault in the primary insulation of the device to trigger safety devices like fuses and residual current devices built inside such devices and prevent shocks.

Class II: These are marked as double-insulated devices. These luminaires have two independent layers of Class II. If one performed layer fails, the risk to the user is very low anyhow. With advancements in materials, Class II devices are known as durable and safe.

Class III: This operates in a mode called Separated Extra-Low Voltage (SELV). This kind of device normally operates below 50 V AC, or 24 V or 12 V DC; Are less than 50 Volt Alternating Current. Because of the low voltage, the risk of electric shock is decreased; this can be applied outdoors with extreme conditions of minimal safety or shielding attached.

Why It Matters:

Understanding these classes is essential not just for compliance, but also for choosing the correct luminaire for a particular environment. For instance, outside or industrial installations are sustained at a higher level of protection class (Class II or III) for more sensitive environments where water exposure is a concern. This practice can significantly decrease the likelihood of dangerous failures. In effect, these classifications guarantee that all installations are provided with the proper amount of insulation, grounding, and fault protection – all of which work to protect equipment and users from harm.

2. More granular classification and new information

2.1 Class 0: Basic Insulation

Overview:

Definition: luminaires of class 0 are provided with output features of basic insulation which is often a simple PVC coating around the wires and does not boast a protective earth connection.

Current Status: In developed markets, Class 0 products are just about extinct due to the stringent requirements of safety. These products have been banned by a lot of nations because the simplest failure of insulation can result in deadly shocks and fire.

Illustration: Older two-pin plug devices and some vintage decorative lighting.

Latest Update: Class 0 luminaries have practically been wiped out in new installations due to modern standards. Class 0 luminaries are gradually becoming impossible to find because manufacturers are designing class 0 lamps to meet the new regulatory requirements which expect higher levels of protection.

2.2 Class I: Earth-Connected Luminaires

Overview:

Definition: These luminaires are backed up with basic insulation along with a protective earthing (ground) connection, which guarantees that every exposed metal part is properly earthed.

Safety Features:

Three-pin plugs (live, neutral, earth)

Built-in fuse or Residual Current Devices (RCDs) for circuit protection

Creepage and clearance distances, such as a minimum of 1.5 mm air gap with a 2.5 mm in earlier versions, and stricter requirements in versions emerging in 2025.

Latest Update:

The 2025 changes have been made to the minimum creepage and clearance distances in Class I luminaires for additional user safety. New technologies in LED drivers have been added that monitor the circuits and provide enhanced real-time failure diagnostics.

2.3 Class II: Double Insulated Luminaires

Overview:

Definition: Double insulated devices, or Class II luminaires, do not need an earth connection since they have two independent insulating layers that protect against electric shock should one insulation layer fail.

Design Characteristics:

Two-pin plug configuration (live and neutral)

The casing is made from durable materials (high-pr-grade plastics or composites)

Wiring and components outside the internal parts are insulated.

Latest Update:

The Class II insulation was improved due to advancements in materials science. The latest designs have products with nano insulation and advanced polymer composite layers which increase product life and have ample safety factors.

2.4 Class III: Separated Extra Low Voltage (SELV) Luminaires

Class III luminaires operate under Separated Extra Low Voltage (SELV) standards and are usually operated under 50 V AC (with a lot of modern equipment operating under 24 V or 12 V DC).

Advantages:

Safer due to narrower voltage limits.

Preferred for use in individual or open locations where more ecological factors can be hazardous.

No additional insulation or protective earth is required since the transformer or LED driver provides isolation by design.

Latest Update:

In 2025, SELV technology will have smart transformers and LED drivers with self-diagnostics and dynamic voltage regulation. These Class III enhancements make them appealing for modern smart city and industrial applications.

3. Additional Safety Symbols and Markings

LED luminaires incorporate safety symbols as one of the main features. These symbols serve as a means of communication between the manufacturers and users regarding the compliance of the product with international safety standards. With the advent of 2025, these signs have become more elaborate and optional.

Key Symbols Explained:

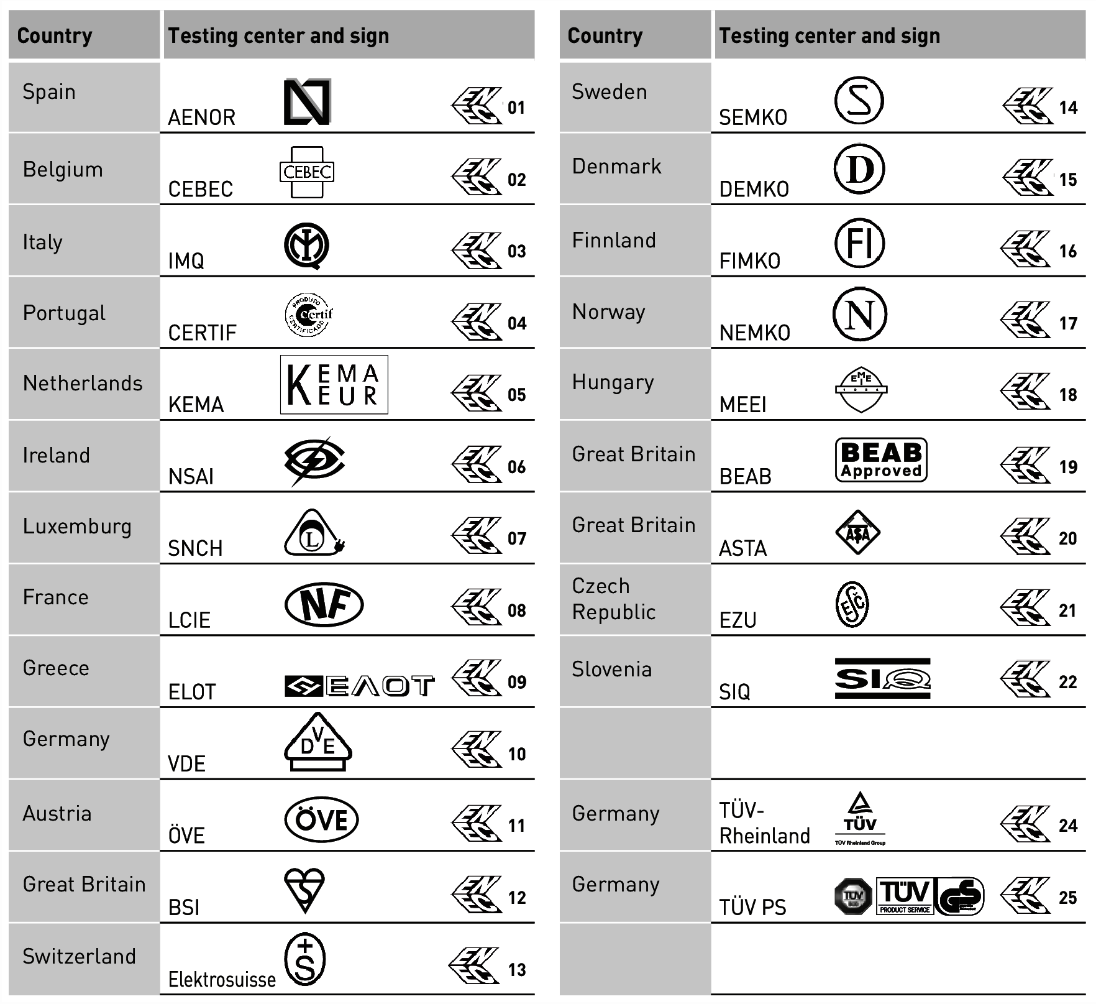

ENEC and VDE Mark: These symbols confirm that the luminaire has passed European (ENEC) and German (VDE) luminaire testing. They have trust marks that imply the product is safe and performs as required.

CE Marking: This marking suggests that the product is certified which clearly indicates the structure adheres to all the EU health, safety and protection measures.

Temperature and Installation Guidelines: New as of 2025. This sign contains precise details about the maximum operating temperature of the device and the recommended installation clearances. For instance, a symbol may suggest use in under 40-degree environments with a minimum mounting distance of 50mm to flammable materials.

Grounding and Insulation Signs: Especially for Class I and II luminaires, these signs indicate that proper earthing or double insulation for protection against electrical faults is put into consideration.

Interactive Digital Certification:

Quite a few modern luminaires possess integrated QR codes handy for installers and end-users which show real-time certification information. Scanning the code enables one to check whether the product meets the most recent IEC standards, including recalls or changes.

Safety Example:

Imagine a commercial setting where a Class I luminaire is used in a busy area. If something goes wrong, like a short circuit due to an insulation fault, the equipment’s integrated residual current device (RCD) will disconnect the supply of power. This level of protection is enhanced by markings on the product, which clearly indicate maintenance issues or dangers, so maintenance personnel can respond safely.

4. Further Installation and Handling Best Practices

There is safe and damage-free use of LED luminaires rest with installation and to some extent, handling. Best practices in this regard have expanded with a view towards 2025 and now include a combination of old conventional approaches alongside newer smart technologies to offer a holistic view on electrical safety.

Pre-Installation Guidelines:

Verification of Certification: Start with the checking of the luminaire’s IEC classification to ensure it fits the project requirements. Verify the issuance of previously described safety symbols, updated digital certifications, and complete installation procedures manuals.

Installation Environment Assessment: Perhaps the most important consideration during preparation is carefully assessing the installation environment. For example, in a humid or water-prone area, choosing a Class II or III luminaire with a higher level of ingress protection may be warranted. As a precaution, determine if there are any risks associated with moisture or dust entering the work area.

Site Conditions: Check that the mounting surface and wiring are up to standard. These surfaces also need to be clean, dry, and properly grounded to eliminate the possibility of short circuits or thermal overload from wiring issues.

While Working on Site:

Cutting Power: A thorough isolation of the circuit is needed before you begin work. This power must not be stored, thus confirming that there is no residual voltage that can harm you is necessary by using a voltage tester and always employing lockout/tagout procedures.

Tools and PPE: Use of protective equipment such as insulated gloves and safety goggles should always be part of the installation, as well as insulated tools. This removes the danger of an accident happening when you make contact with active parts.

Round Mounting and Cabling: Pay attention to the secure mounting and cabling as per the manufacturer’s instructions. If the mounting and clear mounting guidelines are neglected, luminaires may be poorly mounted leading to overheating, insulation breakdown, or even disconnection of the fixture.

Integrated diagnostic characteristics: Advanced modern LED drivers are equipped with automatic self-checks and remote monitoring features. Use these functions to look for loose insulation or joints that are deteriorating and plan maintenance visits according to the system's recommendations.

Safety Example:

During one visit to an industrial site, a maintenance technician found that the power supply to a Class I luminaire was too loose resulting in a flashover. When integrated diagnostic automatic alerts issued their warning, the command was followed rapidly. The bad connection was fixed before it became a danger. This event highlights the necessity of implementing prescribed procedures and safeguarding principles, and supporting modern technologies.

5. Prolonged forthcoming tendencies and changes

It's on the edge of pronounced shifts that will stem from the quick evolution of technologies and growing attention toward smart and interconnected systems. The LED lighting domain, starting in 2025, is expected to innovate redefining safety, efficiency, and user experience.

New Technology Development:

Luminaires with IoT: Nowadays, Almost all today’s luminaires are equipped with IoT sensors that monitor the parameters of voltage, current, temperature, and even ambient light. Performance monitoring, predictive maintenance, and instant alerts in the case of anomalies are all made possible thanks to these sensors. A smart luminaire, for example, might notice a decrease in insulation resistance and notify the maintenance division prior to a breakdown.

Advanced LED drivers and Smart Transformers: The development of transformer technology has led to increased use of smart LED drivers which not only provide Separated Extra Low Voltage (SELV) but also have self-diagnostic capability. Such systems can respond to changes in voltage and instantly alter their output ensuring maximum performance and safety.

New Materials: The use of nanocomposites and advanced polymers is redefining insulation and heat resistance in materials science. Such materials withstand considerably more thermal stress and electrical faults, therefore extending the lifespan of LED luminaires tremendously.

Certification through Blockchain Technology: One of the most innovative advancements is the automation of certification processes through blockchain technology and digital systems. These technologies guarantee that certification information cannot be altered and is readily available through QR codes, granting both installers and end-users instant access to information regarding compliance with the latest IEC regulations.

Example in Safety:

Consider a smart city scenario in which hundreds of outdoor networked LED devices are deployed. Each device individually tracks its operational state and environmental condition. If one luminaire detects a suddenly raised temperature, which could signal either the breakdown of the insulation or an electrical fault taking place, the device immediately calls the central management system. The system is capable of routing a maintenance squad to fix the problem before it leads to failure, accidents, and service interruption.

Future Deployment:

Along with an increasing level of safety in luminaries, the future also holds the promise of more sustainable, energy-efficient solutions. As the implementation of smart lighting systems becomes the norm, additional IoT and blockchain certification will shift the paradigm of safety and performance spine. Such changes mean that users will be empowered to ensure that installations are safe and efficient.

Conclusion

The development of the IEC protection classes for LED luminaires demonstrates the lighting industry's devotion to safety, efficiency, and progressive innovation. While we approach the year 2025, the continuous evolution of sophisticated integration systems along with enhanced materials and heightened protection levels are establishing new standards for both domestic as well as industrial lighting systems. Lighting designers, installers, and end-users alike must be familiar with the relevant class so that everyone can enjoy modern LED lighting with its beauty and safety features.

Illuminate Your Building's Future Now with LNJAMI.

We are a 17-year-old outdoor lighting source factory. Our main products are outdoor wall washers, linear lights, floodlights, point light sources, and other lamps. We generally adhere to providing customers with safe, reliable, and cost-effective products, and we have always paid attention to the protection of LED lamps. We can provide DC12V, DC24V, and AC220V lamps according to customer needs, and we can also provide customized lamps. If you have lighting project needs, please contact us.